- Applications

- Touchscreen Capacitance

Touchscreen Capacitance Computation

Capacitive sensors measure changes in capacitance to detect differences in their environment. They are commonly used as touchscreens to detect the location of fingers or a stylus on the screens of smart phones, tablets, computer screens, music players, and computer touch pads, though many other uses exist in scientific research and industry.

XFdtd can compute the capacitance of complex sensor designs, allowing the designer to choose the best geometry for their needs without prototyping.

Design Requirements

Touchscreen assemblies typically consist of a durable surface, such as glass, on top of one or more layers of transparent conductors, adhesive, and dielectrics. The self- and mutual-capacitance of each conductor is measured by sensing electronics attached to the conductor assemblies.

Changes in this matrix of capacitances represent the location of objects(s) near the screen. It is useful for designers to be able to predict this capacitance matrix for touchscreen designs, including the "rest" value of the matrix when there are no objects to be sensed, and in proximity to fingers, styli, etc.

XFdtd Capabilities for Touchscreen Capacitance Simulations

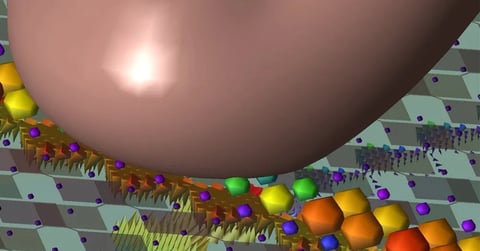

The electrostatic solver in XFdtd can compute the matrix of self- and mutual-capacitance between any number of conductors in the geometry. The geometry can be created within XF or imported from any supported CAD file formats and may be of almost any arbitrary shape and complexity. Simulations can consist of the touchscreen assembly only or may be as complex as the complete device (mobile phone, tablet, etc.) and/or fingers or a stylus, in order to evaluate the installed performance of the sensors. If desired, the transient solver in XF can compute charge and discharge cycles by adding the appropriate components and switching to the touchscreen assembly.

.jpeg?width=500&height=358&name=image-asset%20(4).jpeg)

Analysis of Specific Use Cases

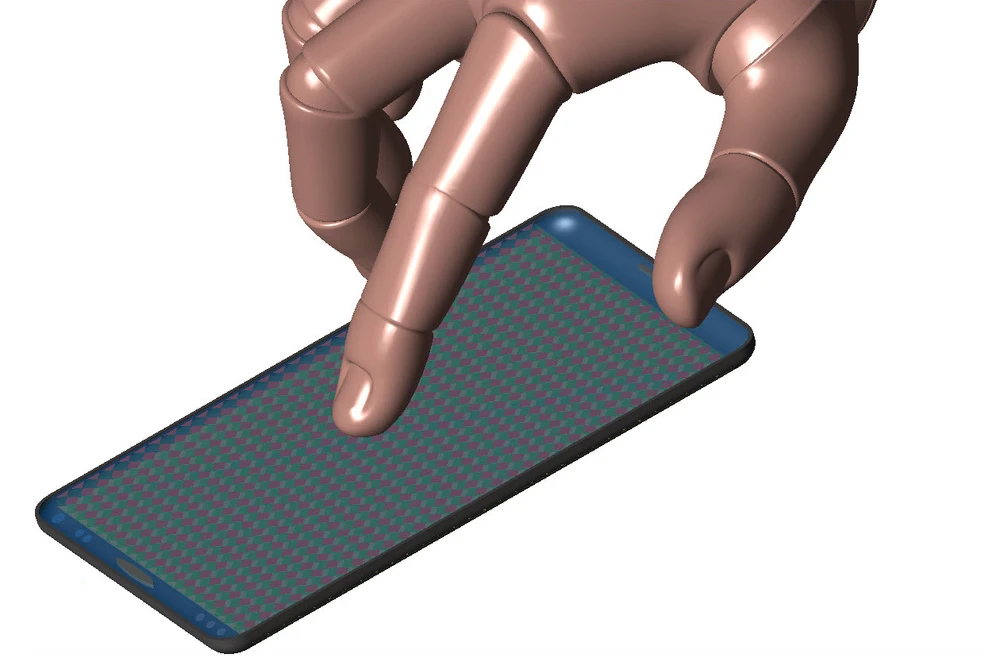

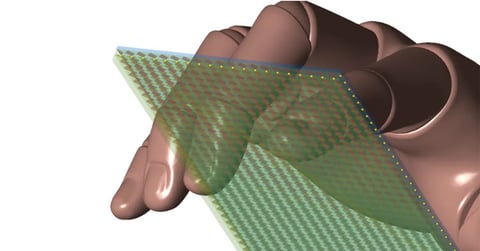

Using XF’s Poseable Hands, many configurations of typical touchscreen usage can be evaluated.

Single Touch

.jpeg)

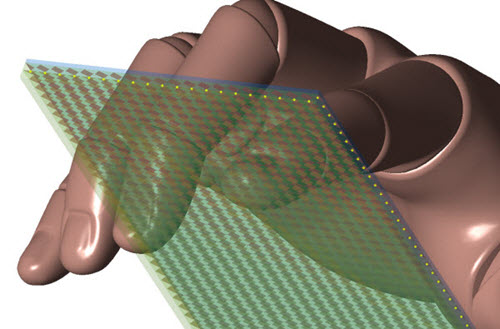

Pinch and Zoom

.jpeg)

Typing

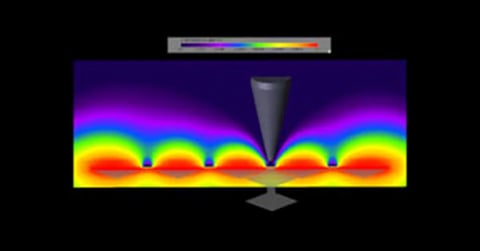

Similarly, a stylus can be analyzed. Using a parameter sweep in XF, the location of the tip can be moved along the displacement line without needing to recreate the stylus for each location.

.jpeg?width=175&height=300&name=image-asset%20(8).jpeg)

.jpeg?width=202&height=300&name=image-asset%20(9).jpeg)

Stylus with 1mm tip

Parameterize tip location

XFdtd Electrostatic Solver Benefits

XF provides the following benefits to designers and manufacturers of touchscreen assemblies and devices:

- Characterize self- and mutual-capacitance matrix for arbitrary, complex sensor designs:

- Touchscreen in isolation

- With one or more objects in proximity (single and multi-touch situations)

- Designs may be imported from CAD in any of XF's supported formats or created from the XF solids modeler

- Compatible with XF’s Poseable Hands and third-party biological files

- Extensive support for complex geometries allows for analysis within fully populated devices

.jpeg?width=428&height=300&name=image-asset%20(10).jpeg)

.jpeg?width=417&height=300&name=image-asset%20(11).jpeg)

Diamond Pattern

Four-square Pattern

Additional Information

-

Webinars

XFdtd's Electrostatic Solver for Touchscreen Design

This webinar demonstrates XFdtd's Electrostatic Solver for touchscreen design. This capability was developed for teams designing sensor and drive lines in touchscreens.

Explore Resource -

Application Examples

Touchscreen 3x4 Diamond Simulation with XF's Electrostatic Solver

The capacitance matrices for a 3x4 touchscreen are analyzed in an unloaded and loaded case. Based on the changes in capacitance, the location of the 1 mm stylus is identified.

Explore Resource -

Brochures

Touchscreen Capacitance Brochure

XFdtd® can compute the capacitance of complex sensor designs, allowing the designer to choose the best geometry for their needs without prototyping.

Explore Resource

Save time and reduce costs.

Contact Remcom today for a customized solution to your most complex electromagnetic challenges.

Request a Quote